3D Resin Printing

Like every company, at 3D Printing Leeds we purchase our 3D Resin Printing machines off-the-shelf from specialist companies but this does not mean those printers are perfect and ready to go. They all need checking and improving and then maintaining.

With our 3D Resin Printers, we found that its fumes were leaking even though the manufacturer had provided some kind of air filter. The lid did not fit well either and the fumes escaped under it.

We found some modifications online that we could 3D Print on our FDM printers but those files were old and did not fit or seal well to the current machine model.

- Fumes extractor MODification

- Charcoal pallets

- Air flow fan

So, true to our business, we re-engineered the part to fit the current manufactures tolerances and then improved on it too.

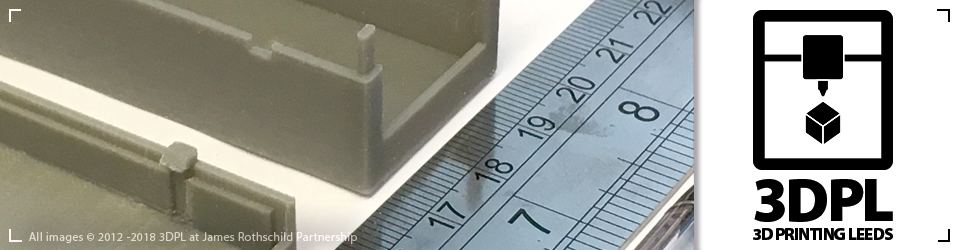

Pictured below is a gasket: we changed the profile to fit tightly to the base unit, to skirt the filter unit (see our previous post on this). We also deepened the channels for the lid to provide a solid firm fit. We also sourced some very thin foam strip to seal both the top and bottom fitment.

- Fume Extractor

- Fume Gasket

Now there are no fumes and no unwanted smells. Success!

Website Showcase: https://www.3dprintingleeds.co.uk/3d-showcase/

Facebook: https://www.facebook.com/3dprintleeds/

Twitter: @3dprintleeds

Instagram: 3dprintingleeds